SiC Silicon Carbide Ceramics

Silicon carbide (SiC) is a ceramic material made of silicon and carbon. It has great properties, such as being hard, resistant to high temperatures and chemical corrosion, and a good electrical and thermal conductor.

Details of SiC Silicon Carbide Ceramics

What is Silicon Carbide Ceramic?

Silicon carbide (SiC) is a compound of silicon and carbon. It is a ceramic material that is used in various applications due to its excellent properties. SiC is a hard and brittle material that is resistant to high temperatures and chemical corrosion. It is also an excellent electrical conductor and has a high thermal conductivity.

Properties of Silicon Carbide Ceramic

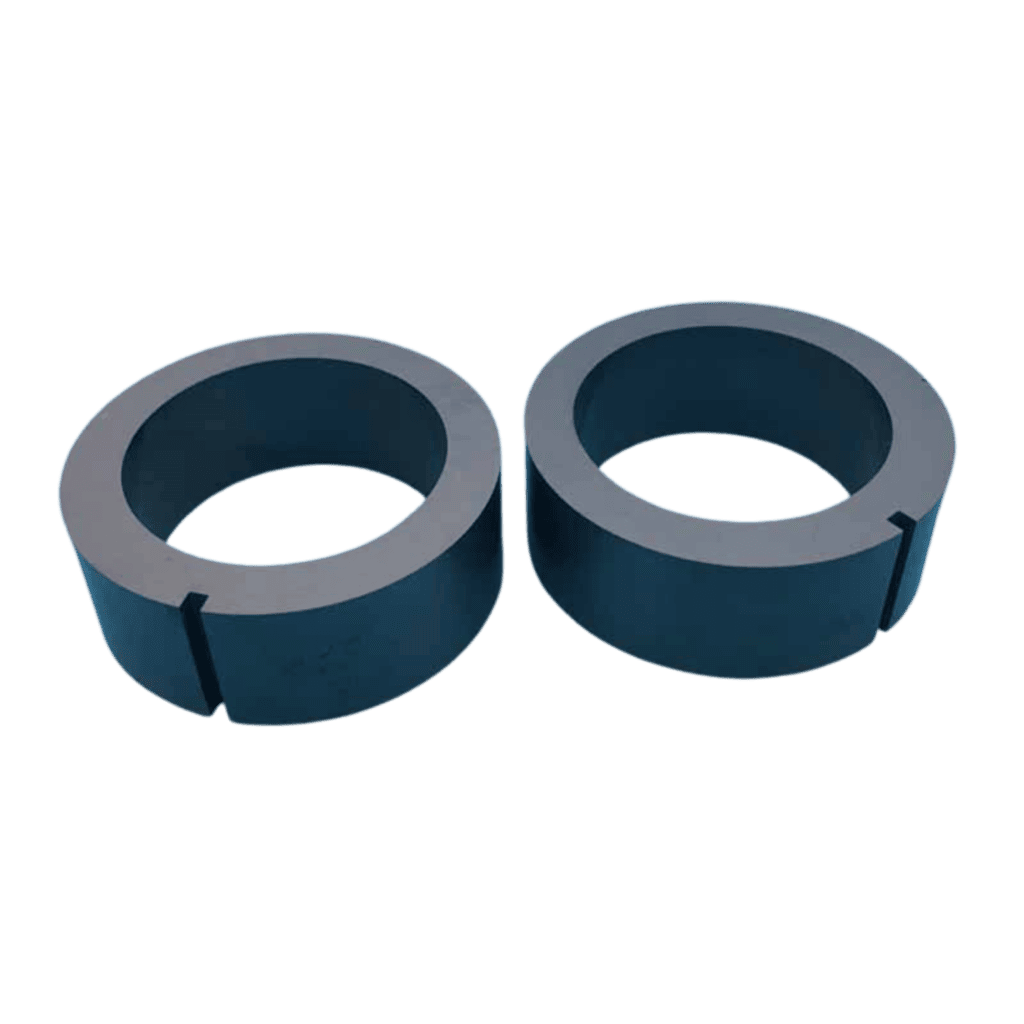

Silicon carbide ceramics can be black or green in color. They are known for their high strength, hardness, and resistance to wear, corrosion, and high temperatures.

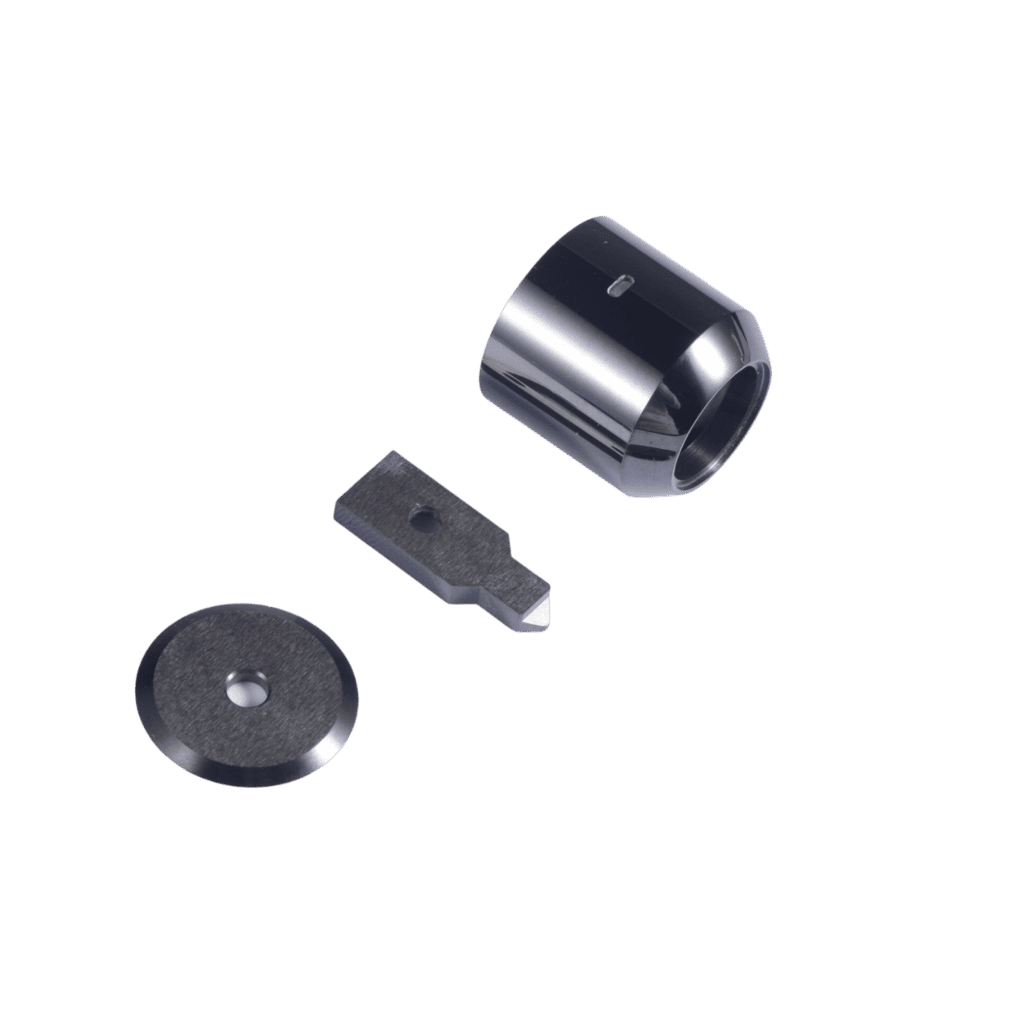

Silicon carbide ceramics are used in a variety of applications, including cutting tools, abrasives, refractory materials, and electronic components. They are also used in the production of semiconductors and LEDs due to their unique electrical properties.

Following is the properties sheet:

| Type | Unit | Test Standard | Silicon Carbide |

| Material | SiC | ||

| Colour | black | ||

| Density | g/cm³ | ISO18754:2003 | 3.15 |

| Flexural strength | Mpa | ASTM-C1161-13 | 400 |

| Compressive Strength | Mpa | GB/T8489-2006 | 2000 |

| Modules of Elasticity (young) | Gpa | ASTM-C1198-09 | 430 |

| Fracture Toughness | MPa*m1/2 | ASTM-C1421-18 | 4 |

| Poision’s Ratio | ASTM-C1421-18 | 0.16 | |

| Hardness HRA | HRA | RICKWELL 60N | 94 |

| Vickers Hardness | HV1 | ASTM-C1327-15 | 2100 |

| Thermal Expansion Coefficient | 10-6K-1 | ASTM-E1461-13 | 3.5 |

| Thermal Conductivity | W/mk | ASTM-E1461-13 | 90 |

| Thermal Shock Resistance | △T.℃ | / | 600 |

| Max Use Temperature in oxidizing Atmosphere | ℃ | NO LOAD CONDITION | 1350 |

| Max use Temperatur in reducing or Inert Atmosphere | ℃ | NO LOAD CONDITION | 1350 |

| Volume Resistivity at 20°C | Ωcm | / | 105 |

| Dielectric Strength | kV/mm | / | 0 |

| Dielectric Constant (1MHN) | ASTM-D2149-13 | / | |

| Dielectric Loss Angle at 20C, 1MHz | tanδ | ASTM-D2149-13 | / |

What Are The Advantages of Silicon Carbide Ceramics?

High strength and hardness: SiC ceramic parts are very hard and have high strength, making them suitable for applications that require high wear resistance and durability.

Thermal shock resistance: SiC ceramic parts can withstand rapid temperature changes without cracking or breaking, making them suitable for high-temperature applications.

Chemical resistance: SiC ceramic parts are resistant to chemical corrosion, making them suitable for applications that involve exposure to harsh chemicals.

Electrical conductivity: SiC ceramic parts are excellent electrical conductors, making them suitable for electronic components.

High thermal conductivity: SiC ceramic parts have a high thermal conductivity, making them suitable for applications that require efficient heat transfer.

What Are The Usages of Silicon Carbide Ceramics?

Silicon carbide ceramics have a wide range of applications due to their unique properties, including:

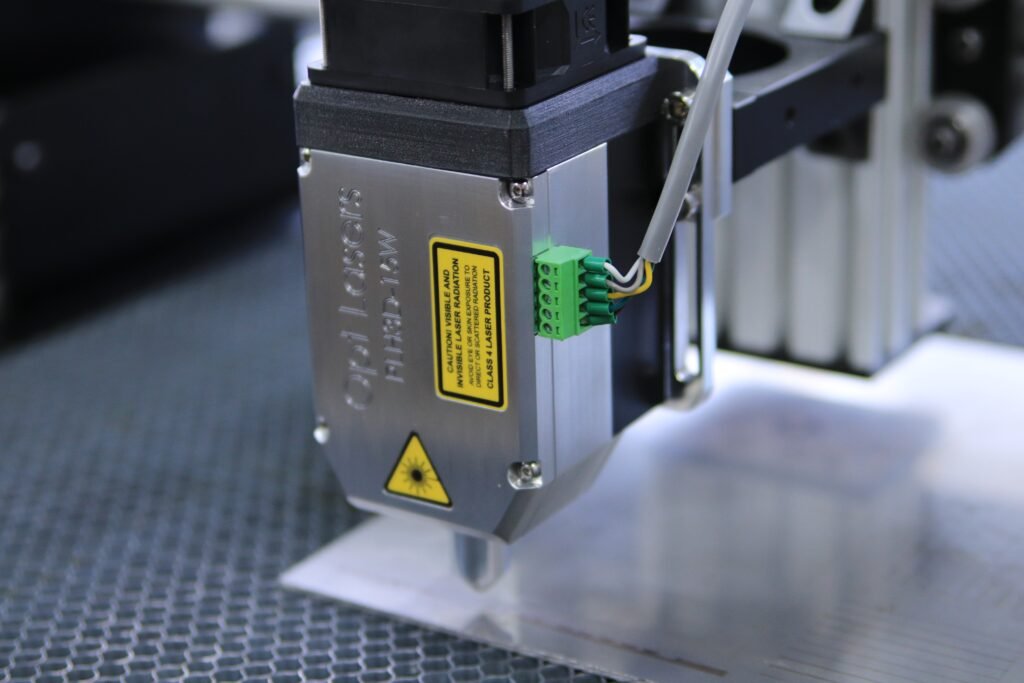

Abrasive: Silicon carbide is used as an abrasive material in grinding wheels, sandpaper, and cutting tools.

Refractory: Silicon carbide ceramics have high melting points and excellent thermal shock resistance, making them ideal for use in refractory applications such as furnace linings and kiln furniture.

Electrical components: Silicon carbide is a semiconductor material with high electrical conductivity, making it useful in electronic components such as diodes, transistors, and sensors.

Armor: Silicon carbide ceramics are used in body armor and vehicle armor due to their high hardness and toughness.

Aerospace: Silicon carbide is used in aerospace applications such as turbine blades and heat shields due to its high strength and thermal stability.

Chemical processing: Silicon carbide ceramics are resistant to corrosion and chemical attack, making them useful in chemical processing applications such as pumps and valves.

Medical implants: Silicon carbide is biocompatible and can be used in medical implants such as artificial joints and dental implants.

Energy storage: Silicon carbide is being researched for use in energy storage devices such as batteries and capacitors due to its high energy density and stability.

Provide ON-SITE GUIDANCE for orders over $500,000

Compared to steel, technical ceramics have the potential to significantly increase the lifespan of equipment and enhance product precision

The whole production process of Silicon Carbide Ceramics

Shaping

Silicon carbide powder shaped into the desired form using a variety of techniques, such as pressing, extrusion, or slip casting. The shaping process is critical to achieving the desired properties of the final product.

Drying

The shaped parts are then dried to remove any moisture and to prepare them for firing.

Firing

The dried parts are fired in a kiln at high temperatures (usually between 140°C and 180°C) to sinter the silicon carbide powder and form a dense, hard ceramic material. The firing process can take several hours to several days, depending on the size and complexity of the parts.

Finishing

After firing, the parts are often machined or polished to achieve the desired surface finish and dimensional accuracy.

Quality Check

After finishing all the production precesses, the parts will be checked one by one to keep them are free from defects, errors, or any other issues that may affect their performance or functionality.

Is It Good As Metals? Things You Need To Know

To save you from worries, here are some facts you need to know about our advanced ceramic parts supplies:

High Temperature Resistance

Advanced ceramics can withstand higher temperatures than most metals, making them ideal for use in high-temperature applications.

Hardness And Wear Resistance

Structural ceramics are much harder and more wear-resistant than metals, making them ideal for use in applications where wear and tear are a concern.

Corrosion Resistance

Ceramics are highly resistant to corrosion, making them ideal for use in harsh environments where metals would quickly corrode.

Electrical Insulation

Ceramics are excellent electrical insulators, making them ideal for use in electrical and electronic applications.

Biocompatibility

Some advanced ceramics are biocompatible, meaning they can be used in medical applications without causing harm to the body.

Lightweight

Ceramics are generally lighter than metals, making them ideal for use in applications where weight is a concern.

Low Thermal Expansion

Ceramics have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with changes in temperature, making them ideal for use in precision applications.